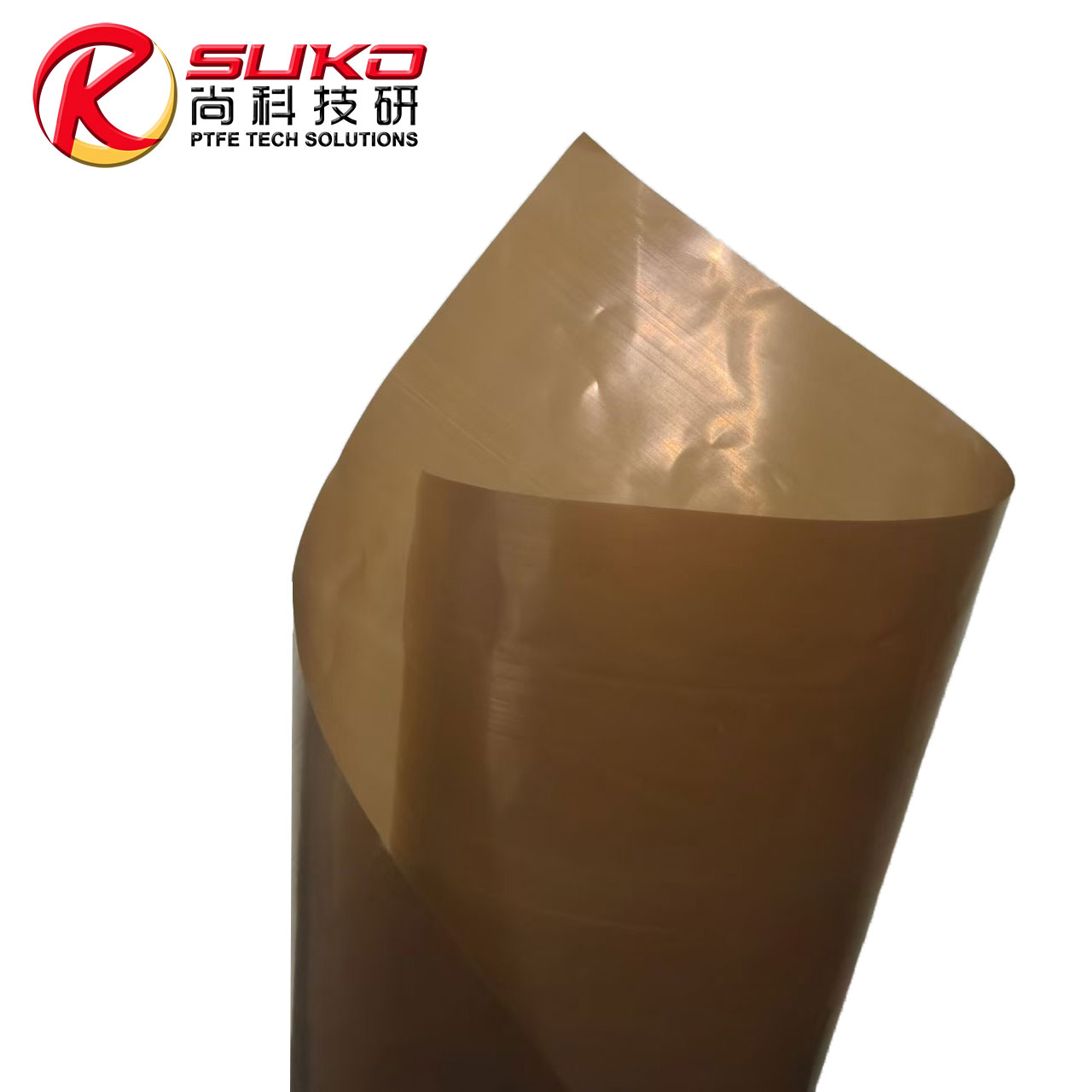

Double-Sided Etched PTFE Film for Bonding

Product Overview

SuKo’s Double-Sided Etched PTFE Film is a high-performance PTFE etched membrane designed for superior bonding in demanding industrial applications. This double-sided etched PTFE film offers exceptional low friction PTFE properties and chemical resistant PTFE characteristics, making it an ideal choice for industries such as electronics, aerospace, and advanced composites manufacturing. The double-sided etching process enhances adhesion, allowing the film to bond securely with various substrates, including resins, metals, rubber, plastics, and other non-metal materials. This PTFE bonding film is engineered to deliver durability, reliability, and performance in harsh environments, ensuring long-lasting results for high-performance applications.

For more information or to request a quote, please contact us at info@sukoptfe.com or visit our contact page.

Key Features

- Enhanced Adhesion: Double-sided etching modifies the surface of the PTFE etched membrane, enabling strong bonding to a wide range of substrates, including resins, metals, and composites.

- Low Friction PTFE: Exhibits an extremely low coefficient of friction, ideal for applications requiring smooth surface movement and reduced wear.

- Chemical Resistant PTFE: Highly resistant to acids, bases, solvents, and other aggressive chemicals, ensuring stability in harsh chemical environments.

- Thermal Stability: Operates effectively across a wide temperature range, from -200°C to +260°C, suitable for high-temperature and cryogenic conditions.

- Non-Stick Properties: Inherent non-stick surface minimizes adhesion of unwanted materials, making it ideal for mold release and non-stick coating applications.

- Electrical Insulation: Low dielectric constant and excellent dielectric strength make it perfect for electronics applications, such as capacitor films and wire harnesses.

- Durability: High tensile strength and tear resistance ensure long-term performance in demanding industrial applications.

- Customizable: Available in various thicknesses, widths, and roll lengths to meet specific application needs.

Applications

SuKo’s double-sided etched PTFE film is versatile and widely used across multiple industries due to its unique combination of properties. Key applications include:

- Electronics: Used as an insulating material in capacitor films, wire harnesses, and circuit boards due to its excellent dielectric properties and chemical resistant PTFE characteristics.

- Aerospace: Employed in aerospace engineering for protective barriers, gaskets, and seals, offering low friction PTFE and resistance to extreme temperatures and chemicals.

- Composites Manufacturing: Ideal as a PTFE bonding film for secure adhesion in high-performance composites, ensuring durability and reliability in structural components.

Chemical Processing: Used in chemical resistant PTFE liners, seals, and diaphragms for handling corrosive substances in chemical processing equipment. - Medical Devices: Biocompatible and non-reactive, suitable for medical tubing, catheters, and non-stick surfaces in medical applications.

- Industrial Applications: Serves as a mold release film, release liner, or low friction PTFE coating for machinery components like bearings, gears, and slide plates.

- Solar Panels: Acts as a backsheet material in photovoltaic modules, providing durability and chemical resistance.

- Packaging: Utilized as a release liner for adhesive-backed materials and heat-sealing surfaces in packaging applications.

Product Parameters

| PRODUCTS | PTFE ACTIVATION FILM | |||||

| PRODUCTS CONSTRUCTION | PTFE SURFACETREATMENT | |||||

| BASIC MATERIAL | ||||||

| MATERIAL NAME | PTFE | TENSILE STRENGTH | About 8 Mpa | |||

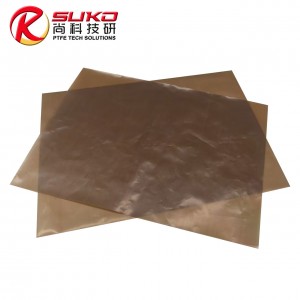

| THICKNESS | 0.03mm±0.01mm | ELONGATION | 80% | |||

| SPECIFIC GRAVITY | 2.2g/㎝³ | TEMPERATURE RANGE | -70℃~260℃ | |||

| COLOR | BLACK | MOLD SHRINKAGE | 60Mpa | |||

| SMOOTHNESS | GGOD | DIELECTRIC CONSTANT(106HZ) | 1.8~2.2 | |||

| WATER CONTACT ANGLE(BEFORE TREAT) | 118° | SURFACE RESISTIVITY | 1016Ω | |||

| SURFACETREATMENT(ACTIVATION) | ||||||

| TREATMENT TYPE | CHEMISTRY TREAT | EVENNESS | GOOD | |||

| TREATMENT LIQUID | NAPHTHALINE-NATRIUM LIQUID | TEMPERATURE RANGE | -70℃~260℃ | |||

| THICKNESS | 0.2um | WATER CONTACT ANGLE(ATFER TREAT) | 30° | |||

| COLOR | BROWN | WEATHER RESISTANCE | NORMAL | |||

| 1、THE TECHNIAL DATE ARE BASED ON THE SPECIAL ENVIRONMENT AND LABORATORY.YOU SHOULD ACCORDING TO DIFFERENT CONDITION IN DIFFEREEN WAYS. 2、PTFE’S PERFORMANCES SHOULD NOT CHANGE AFTER SURFACETREATMENT.IT ONLY CHANGE THE WATER CONTACT ANGLE. 3、PLEASE KEEP IT WITHOUT HIGH TEMPERATURE AND SUNSHINE. |

||||||

Note: Custom specifications, including thickness, width, and roll length, are available to meet your specific requirements. Contact us at info@sukoptfe.com for tailored solutions.

Why Choose SuKo’s Double-Sided Etched PTFE Film?

- Superior Quality: Manufactured using high-quality virgin PTFE resins, ensuring consistent performance and reliability.

- Advanced Etching Technology: Our proprietary double-sided etching process enhances adhesion without compromising the core properties of low friction PTFE or chemical resistant PTFE.

- Industry Expertise: With over 13 years of experience in PTFE manufacturing, SuKo delivers innovative and high-quality PTFE etched membrane solutions.

- Customization: We offer tailored solutions to meet specific application needs, including custom thicknesses, widths, and surface treatments.

- Global Reach: Trusted by industries worldwide, with a strong reputation in electronics, aerospace, and chemical processing markets.

- Quality Assurance: All products are manufactured under stringent quality control processes and comply with CE, ISO, SGS, and FDA standards (for specific grades).

Bonding and Etching Process

The double-sided etched PTFE film undergoes a chemical etching process that modifies the surface at a molecular level, enabling strong adhesion to various substrates. This process involves:

- Surface Preparation: The PTFE surface is treated with a chemical etchant, removing fluorine molecules to create a reactive surface.

- Enhanced Bonding: The etched surface allows secure bonding with resins, metals, rubber, and other materials, making it ideal for composites and industrial applications.

- Preservation of Properties: Etching affects only the top few molecular layers, preserving the low friction PTFE and chemical resistant PTFE properties of the film.

For optimal bonding, we recommend storing etched films in controlled environments to maintain surface reactivity. Water contact angle measurements can be used to verify etching quality for consistent adhesion performance.

Industries Served

- Electronics: Capacitor films, wire harnesses, and circuit board insulation.

- Aerospace: Protective barriers, gaskets, and seals for extreme environments.

- Chemical Processing: Liners, seals, and diaphragms for corrosive applications.

- Medical: Biocompatible components for medical devices and tubing.

- Automotive: Low-friction components for gears, bearings, and slide plates.

- Renewable Energy: Backsheet material for solar panels and fuel cell components.

How to Order

For detailed product information, samples, or pricing, please reach out to our team:

- Email: info@sukoptfe.com

- Website: https://www.sukoptfe.com/

- Contact Page: https://www.sukoptfe.com/contact/

SuKo is committed to providing high-performance double-sided etched PTFE film tailored to your specific needs. Let us help you enhance your industrial applications with our advanced PTFE bonding film.