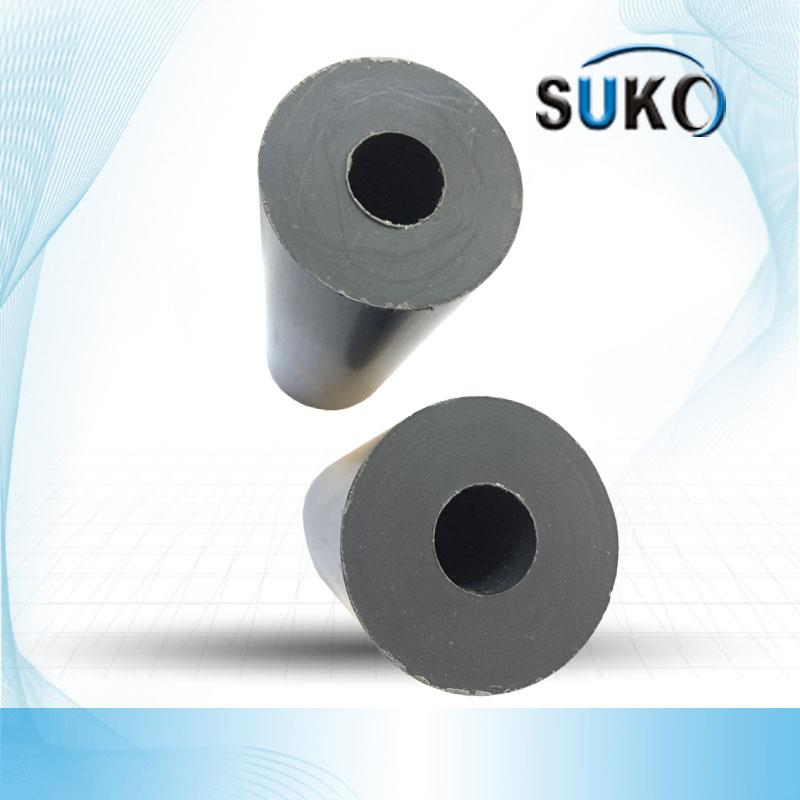

Premium PTFE Lining Pipe for Superior Chemical Resistance - Shop Now

Introducing SuKo Polymer Machine Tech Co., Ltd., a leading manufacturer, supplier, and factory in China, renowned for its exceptional range of high-quality products. One of their remarkable offerings is the PTFE Lining Pipe, designed to cater to various industrial applications. PTFE Lining Pipes are a reliable solution for handling corrosive and aggressive media. These pipes are constructed using state-of-the-art technology and the finest quality materials, ensuring unmatched durability and performance. The PTFE lining acts as a barrier, protecting the piping system from highly corrosive substances and preventing leaks, contamination, and damage. From chemical processing plants to industrial waste disposal facilities, these PTFE Lining Pipes are an essential component, meeting the specific requirements and demands of diverse industries. SuKo Polymer Machine Tech Co., Ltd.'s expertise in polymer engineering guarantees exceptional manufacturing standards, offering customers a reliable and long-lasting solution. If you are looking for a trusted manufacturer, supplier, and factory for PTFE Lining Pipes, SuKo Polymer Machine Tech Co., Ltd. is your ideal choice. Experience their commitment to quality, prompt customer service, and competitive pricing. Invest in their highly durable PTFE Lining Pipes for a secure and efficient piping system in your industrial operations.

Related Products