Teflon Machining Services: Precision Solutions for Any Application

Introducing Teflon Machining by SuKo Polymer Machine Tech Co., Ltd., a leading manufacturer, supplier, and factory based in China. Teflon, a brand name widely recognized for its exceptional non-stick properties, is extensively used in various industries. We take pride in our expertise in Teflon machining, offering reliable and precise manufacturing solutions to cater to diverse customer requirements. At SuKo Polymer Machine Tech Co., Ltd., we utilize state-of-the-art machinery and the latest manufacturing techniques to produce high-quality Teflon components. Our team of skilled engineers and technicians ensures strict adherence to industry standards, resulting in exceptional precision and durability. With our extensive product range, we are equipped to handle both small and large-scale orders efficiently, catering to clients worldwide. Whether you need custom-designed Teflon parts or off-the-shelf components, our flexible manufacturing capabilities allow us to fulfill your specific needs promptly. As a trusted supplier, our commitment to customer satisfaction is unwavering. We prioritize providing exceptional service, competitive pricing, and on-time delivery. Partner with SuKo Polymer Machine Tech Co., Ltd. for all your Teflon machining needs and experience the finest quality products from China.

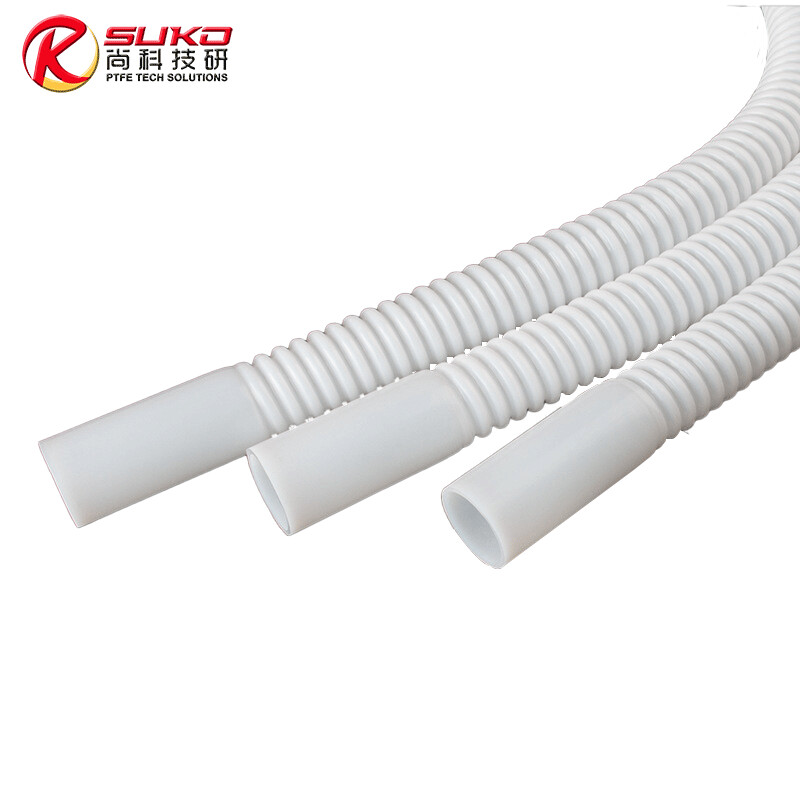

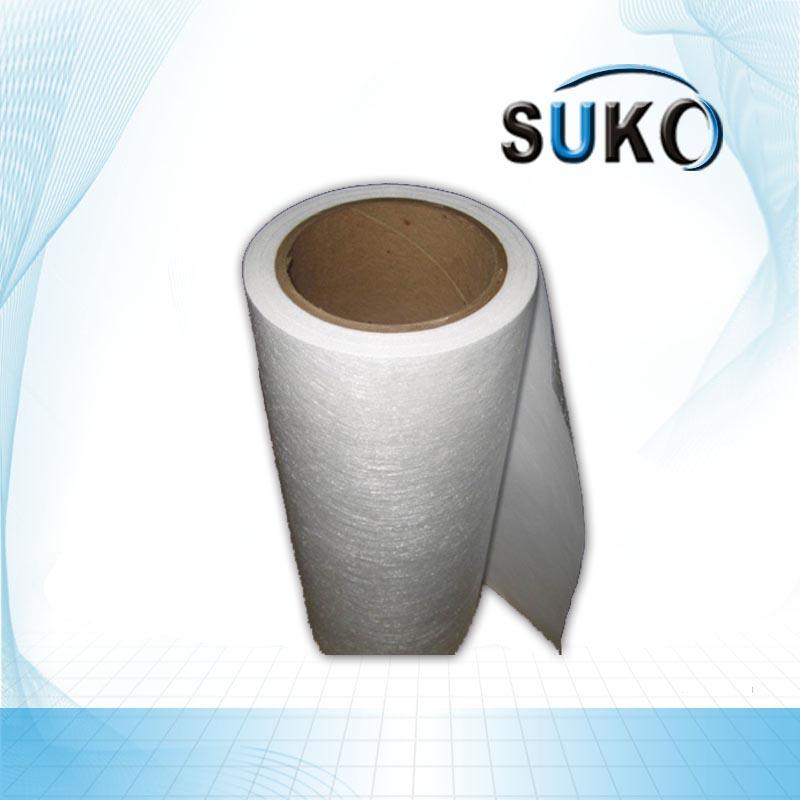

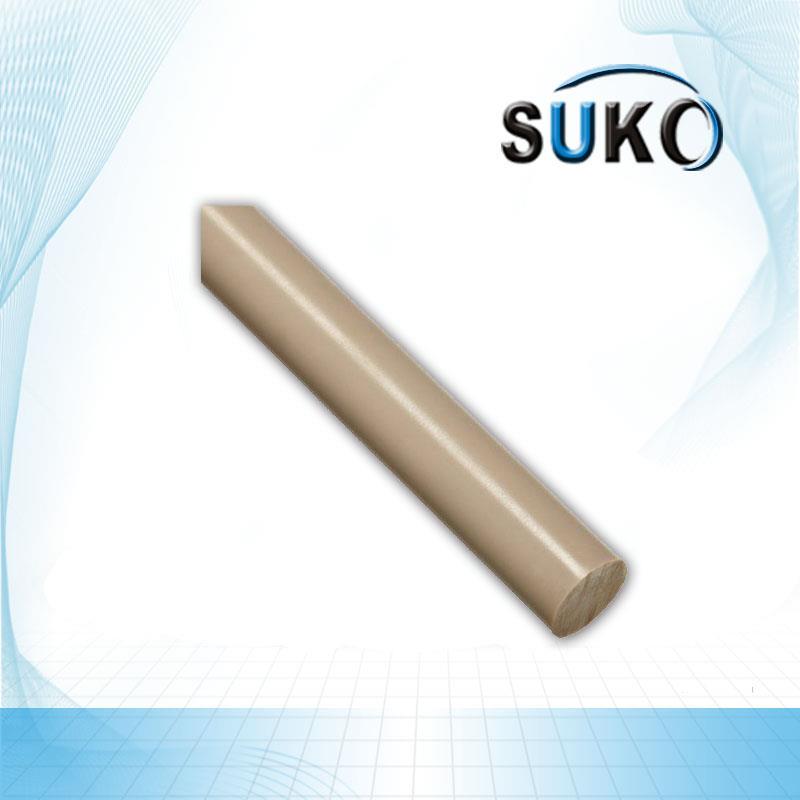

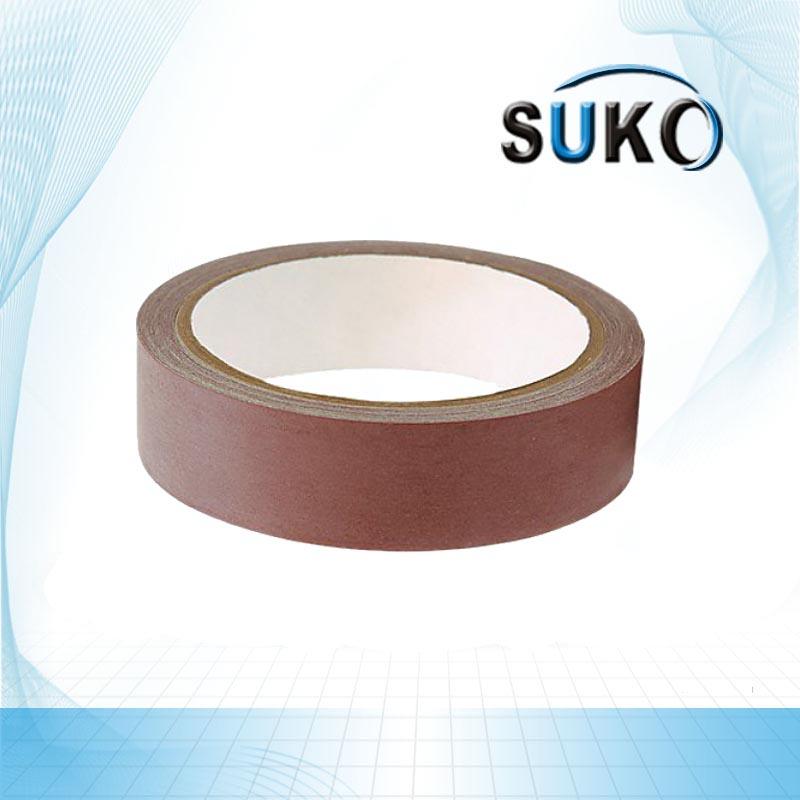

Related Products